The global adhesive equipment market size attained a value of nearly USD 40.14 billion in 2023. The market is further estimated to grow in the forecast period of 2024-2032 at a CAGR of 5.6% to reach a valuation of about USD 65.55 billion by 2032. This growth is driven by the increasing demand for adhesive solutions across multiple industries, including automotive, packaging, construction, and electronics. As manufacturers continue to focus on automation, precision, and sustainability, the role of adhesive equipment is becoming even more crucial in optimizing production processes and ensuring high-quality end products.

In this blog post, we will delve into the various segments of the adhesive equipment market, examining key products, applications, regional trends, market dynamics, and future growth prospects. With rising industrial automation and the constant evolution of adhesive technology, the adhesive equipment market is poised for sustained growth.

Overview of the Global Adhesive Equipment Market

Adhesive equipment plays a pivotal role in modern manufacturing by facilitating the application of adhesives used in bonding, sealing, and coating processes. From industrial applications to DIY projects, adhesive equipment is integral to ensuring product integrity and performance. As industries seek faster production cycles, improved efficiency, and eco-friendly alternatives, the demand for advanced adhesive equipment continues to rise.

The global adhesive equipment market is expected to witness steady growth, fueled by the ongoing expansion of industries that rely on adhesive solutions. Technological advancements, including automation, smart systems, and energy-efficient equipment, are also contributing to the market’s rapid development. In particular, the packaging, automotive, and electronics industries are experiencing a surge in demand for innovative adhesive applications.

Market Segmentation by Product

Industrial Hot Melt Adhesive Equipment

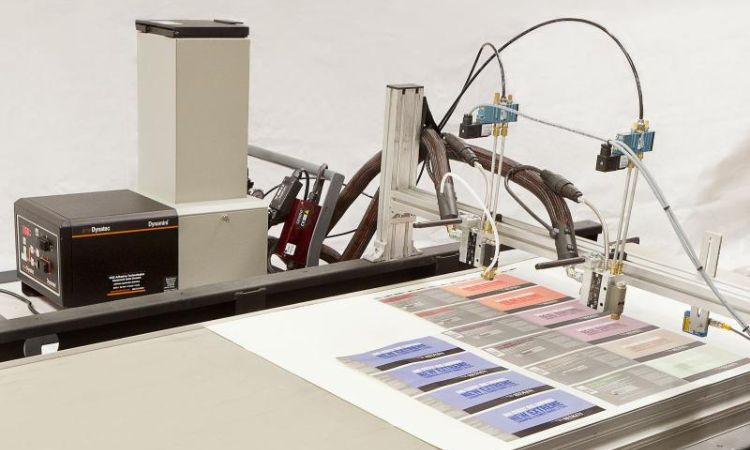

Industrial hot melt adhesive equipment remains one of the most widely used in various industries, particularly in packaging, automotive, and electronics. These adhesives, which are applied while in a molten state, are known for their fast-drying properties and strong bonding capabilities. Hot melt adhesives are extensively used for carton sealing, product assembly, and labeling. The market for industrial hot melt adhesives is growing due to their ability to improve production speed and reduce energy consumption in comparison to traditional adhesive methods.

Technological innovations in hot melt adhesive systems are driving this growth. For instance, systems that offer higher accuracy and the ability to work with a broader range of materials are gaining popularity in industries where precision is critical.

Adhesive Controllers

Adhesive controllers are devices that ensure consistent and accurate application of adhesives. These controllers regulate factors such as adhesive flow, pressure, and temperature, making them essential for ensuring product quality in industries like automotive and electronics. Adhesive controllers also play a crucial role in automating the adhesive application process, reducing human error and enhancing efficiency.

The demand for adhesive controllers is increasing due to the growing adoption of automated manufacturing systems. With the rise of Industry 4.0, many companies are integrating smart adhesive controllers that offer real-time monitoring, predictive maintenance, and advanced diagnostics, further improving production efficiency.

Pneumatic Adhesive Applicators

Pneumatic adhesive applicators use compressed air to apply adhesives with precision. These systems are often used in high-volume production environments, such as automotive assembly lines or in the manufacturing of consumer electronics. Pneumatic applicators are popular for their reliability and cost-effectiveness, especially in large-scale manufacturing processes that require consistent and high-speed adhesive application.

As industries continue to demand faster production cycles, the use of pneumatic adhesive applicators is expected to rise. New advancements, such as energy-efficient models and designs that minimize downtime, are also contributing to the growth of this segment.

Cold Glue Applicators

Cold glue applicators, which apply adhesives at lower temperatures, are commonly used in industries where slower curing times and lower application temperatures are required. These systems are especially popular in packaging, printing, and labeling applications. The cold glue market is growing, particularly as industries seek adhesives that offer stronger bonds at lower energy costs.

In addition to cost benefits, cold glue applicators offer versatility, as they can be used with a wide range of adhesives that are suitable for different materials. With increasing demand for sustainable packaging solutions, the cold glue applicator market is expected to continue expanding.

Adhesive Pumping Systems

Adhesive pumping systems are integral to managing and distributing adhesives efficiently across production lines. These systems ensure that the correct amount of adhesive is applied at the right time, minimizing waste and improving process control. As industries move towards more automated solutions, adhesive pumping systems are becoming more sophisticated, featuring improved flow rate control, higher precision, and integration with other manufacturing systems.

The market for adhesive pumping systems is expected to grow as manufacturers continue to invest in high-throughput systems that can handle a variety of adhesive types and viscosities.

Adhesive Application Guns

Adhesive application guns are widely used in smaller-scale operations, particularly in construction, DIY, and repair industries. These handheld devices provide a simple, cost-effective way to apply adhesives in precise amounts. The growing DIY culture and increased home renovation activities are driving demand for adhesive application guns.

Additionally, with the development of cordless, battery-operated models, the ease of use and portability of these guns have been significantly enhanced, further expanding their appeal to the consumer market.

Market Segmentation by Application

Packaging Industry

The packaging industry is one of the largest consumers of adhesive equipment. Adhesives are used for carton sealing, labeling, and product assembly in various packaging formats. As e-commerce continues to grow, the demand for sustainable and efficient packaging solutions is driving the need for advanced adhesive equipment. Hot melt adhesives, cold glues, and pressure-sensitive adhesives are commonly used in this sector to enhance packaging durability and performance.

Automotive Industry

In the automotive industry, adhesives are increasingly being used for bonding, sealing, and soundproofing purposes. Automotive manufacturers are opting for adhesives over traditional mechanical fasteners to reduce vehicle weight and enhance performance, particularly in electric vehicles (EVs). Adhesive equipment, such as applicators and controllers, is essential for ensuring high precision and quality in the bonding of materials like metals, plastics, and glass.

As the automotive industry continues to innovate, particularly in the development of lightweight vehicles and EVs, the demand for specialized adhesive equipment is expected to increase significantly.

Electronics and Consumer Goods

Adhesive equipment is also crucial in the electronics sector, where adhesives are used for assembling devices, including smartphones, computers, and televisions. With the increasing miniaturization of electronics, precision in adhesive application has become more important than ever. Adhesive controllers, applicators, and pumps are essential in ensuring that the adhesive is applied in the correct quantities and in the right places, thus enhancing the reliability and durability of electronic devices.

The consumer goods sector, which includes household appliances, furniture, and packaging, also relies on adhesive equipment to improve product quality and production efficiency.

Construction and DIY

In the construction sector, adhesive equipment is used for a wide range of applications, from tiling and flooring to the bonding of building materials. Cold glue applicators and industrial adhesive dispensers are commonly used to ensure secure and long-lasting bonds in construction projects.

The DIY market is another growing segment for adhesive equipment, with consumers increasingly relying on adhesive products for home improvement and repair projects. The ease of use of adhesive guns, along with the availability of a variety of adhesives for different applications, is driving growth in this area.

Regional Analysis

North America

North America is one of the largest markets for adhesive equipment, driven by the presence of major manufacturing industries and a strong emphasis on innovation. The U.S. and Canada are key markets for automotive, electronics, and packaging industries, all of which have high demand for adhesive equipment. Furthermore, technological advancements and the integration of smart adhesive systems are helping to fuel market growth in the region.

Europe

In Europe, countries like Germany, the U.K., and France are seeing strong growth in the adhesive equipment market, particularly in industries such as automotive, aerospace, and electronics. The region’s focus on sustainability and energy efficiency is also driving the demand for eco-friendly adhesive solutions. As European manufacturers seek to reduce their carbon footprints, the adoption of energy-efficient adhesive equipment is expected to rise.

Asia Pacific

Asia Pacific is the fastest-growing region for adhesive equipment, largely due to the rapid industrialization in countries like China, India, and Japan. The automotive, electronics, and packaging sectors in these countries are expanding at a rapid pace, driving demand for adhesive equipment. Additionally, the shift towards more sustainable and cost-effective production methods is contributing to the increasing adoption of advanced adhesive equipment.

Latin America and Middle East & Africa

In Latin America and the Middle East & Africa, the market for adhesive equipment is growing, driven by the expansion of the packaging, construction, and automotive industries. While these regions face challenges related to infrastructure and political instability, the increasing demand for industrial automation and advanced manufacturing techniques is helping to boost market growth.

Competitive Landscape

The adhesive equipment market is highly competitive, with several established players and emerging companies vying for market share. Key market players such as Nordson Corporation, Graco Inc., ITW Dynatec, and SAMES KREMLIN are leading the industry, offering a range of advanced adhesive application solutions. These companies focus on product innovation, efficiency, and customer service to maintain a competitive edge.

The market is also witnessing the entry of new players that focus on niche segments or offer specialized solutions, such as eco-friendly adhesive systems or smart adhesive controllers. Strategic partnerships, mergers, and acquisitions are expected to further shape the competitive landscape over the coming years.