Metal Forming Machine Tools Market Outlook

The global Metal Forming Machine Tools Market is positioned for substantial growth with an anticipated Compound Annual Growth Rate (CAGR) of 4% during the forecast period from 2024 to 2032. This growth is driven by various factors, including the increasing demand for automation in manufacturing processes, the rise of Industry 4.0, and the expanding use of advanced metal forming techniques across multiple industries, such as automotive, aerospace, defense, and construction. Additionally, the need for lightweight materials and the drive for energy-efficient manufacturing processes are contributing to the market’s acceleration.

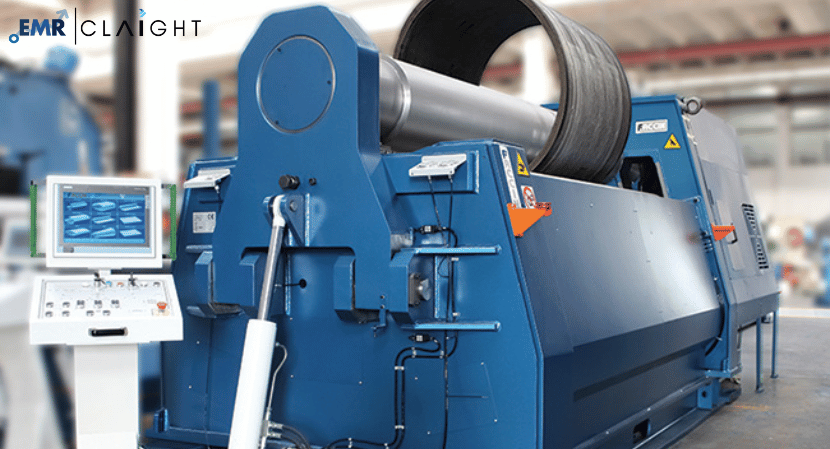

As industries strive to enhance production efficiency and product quality, the adoption of metal forming machine tools is expected to witness a steady rise. These tools, which include press brakes, stamping machines, shearing machines, and others, offer precision and efficiency in shaping metal components, making them integral to modern manufacturing operations.

Market Dynamics and Growth Drivers

The growing emphasis on reducing production time and costs in industries such as automotive and aerospace is a major driver for the metal forming machine tools market. Metal forming tools enable manufacturers to produce complex shapes and high-precision components with reduced material wastage. Furthermore, the shift towards electric vehicles (EVs) and lightweight vehicles is prompting manufacturers to adopt advanced metal forming technologies to produce lighter yet stronger components.

Another significant growth driver is the increasing adoption of automation and robotics in metal forming processes. Automated metal forming machines enhance operational efficiency, reduce human errors, and enable mass production with consistent quality. As industries continue to digitalize their manufacturing processes, the demand for automated metal forming tools is expected to rise.

Competitive Landscape and Key Players

The Metal Forming Machine Tools Market is highly competitive, with several key players striving to maintain their market share through product innovation, strategic partnerships, and geographic expansion. Leading companies are investing in research and development (R&D) to create cutting-edge machines that cater to the evolving needs of industries.

Key players in the market include Amada Holdings Co., Ltd., Trumpf Group, DMG Mori Co., Ltd., and Schuler Group. These companies are focusing on developing innovative products with enhanced features such as energy efficiency, higher precision, and integration with Industry 4.0 technologies. Additionally, mergers and acquisitions are common strategies employed by these companies to expand their product portfolios and strengthen their market presence.

Get a Free Sample Report with Table of Contents @ https://www.expertmarketresearch.com/reports/metal-forming-machine-tools-market/requestsample

Regional Market Analysis

The Metal Forming Machine Tools Market is segmented based on region, with North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa being the key markets. Among these regions, Asia-Pacific is expected to dominate the market, driven by the rapid industrialization and expansion of manufacturing sectors in countries such as China, India, and Japan.

China, in particular, is a major player in the metal forming machine tools market due to its strong manufacturing base and government initiatives to boost domestic production. The increasing demand for high-quality metal components in industries such as automotive and electronics is further propelling the market growth in the region.

Europe is another significant market, with countries such as Germany, Italy, and the UK being at the forefront of metal forming technology. The presence of leading automotive manufacturers and the increasing adoption of Industry 4.0 technologies are driving the demand for advanced metal forming machines in this region.

North America, led by the United States, is also a key market for metal forming machine tools, particularly in industries such as aerospace, defense, and automotive. The region’s focus on technological advancements and automation is expected to contribute to the market’s steady growth.

Market Segmentation

The Metal Forming Machine Tools Market can be segmented based on technology, application, and end-use industry.

- By Technology: The market is categorized into mechanical, hydraulic, pneumatic, and electric metal forming machines. Mechanical metal forming machines are widely used due to their high-speed operation and cost-effectiveness. However, electric machines are gaining traction due to their energy efficiency and precision in complex forming processes.

- By Application: Metal forming machine tools are used in various applications such as stamping, bending, shearing, and forming. Stamping machines are widely adopted in the automotive and electronics industries due to their ability to produce large volumes of precise metal parts.

- By End-Use Industry: The end-use industries for metal forming machine tools include automotive, aerospace and defense, construction, electronics, and general manufacturing. The automotive industry holds a significant share in the market, driven by the demand for lightweight and high-strength metal components. The aerospace and defense sectors also contribute to market growth due to the need for precision metal parts in aircraft and defense equipment.

Trends Shaping the Metal Forming Machine Tools Market

Several trends are shaping the future of the Metal Forming Machine Tools Market:

- Integration of Industry 4.0 Technologies: The adoption of Industry 4.0 technologies, such as the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data, is revolutionizing the metal forming machine tools industry. Manufacturers are increasingly integrating these technologies into their machines to enhance real-time monitoring, predictive maintenance, and process optimization.

- Rising Demand for Lightweight Materials: The demand for lightweight materials, particularly in the automotive and aerospace industries, is driving the adoption of advanced metal forming technologies. Metal forming tools are essential for shaping lightweight metals such as aluminum and titanium, which are increasingly used to improve fuel efficiency and reduce emissions.

- Sustainability and Energy Efficiency: With increasing environmental concerns, manufacturers are focusing on developing energy-efficient metal forming machines. These machines consume less power and generate less waste, aligning with the growing demand for sustainable manufacturing practices.

- Expansion of the Electric Vehicle Market: The shift towards electric vehicles (EVs) is creating new opportunities for the metal forming machine tools market. EV manufacturers require high-precision metal parts for electric motors, batteries, and chassis components, driving the demand for advanced forming technologies.

- Technological Advancements in Metal Forming Tools: Ongoing technological advancements in metal forming tools, such as the development of servo-driven presses and high-speed forming machines, are enhancing the efficiency and accuracy of metal forming processes. These advancements are expected to fuel the market’s growth by catering to the evolving needs of industries.

Challenges in the Metal Forming Machine Tools Market

Despite the promising growth prospects, the Metal Forming Machine Tools Market faces certain challenges. One of the key challenges is the high initial cost of advanced metal forming machines. Small and medium-sized enterprises (SMEs) may find it difficult to invest in these machines due to budget constraints, which can limit market growth.

Additionally, the shortage of skilled labor in the manufacturing sector is another challenge faced by the market. Operating and maintaining advanced metal forming machines require specialized skills, and the lack of trained professionals can hinder the adoption of these technologies in certain regions.

Opportunities in the Metal Forming Machine Tools Market

The Metal Forming Machine Tools Market offers several opportunities for growth and innovation.

- Emerging Markets: Developing economies, particularly in Asia-Pacific and Latin America, present significant growth opportunities for the metal forming machine tools market. The rapid industrialization and growing manufacturing sectors in these regions are driving the demand for metal forming machines.

- Customization and Flexibility: Manufacturers are increasingly seeking flexible and customizable metal forming machines that can be tailored to specific production needs. Companies that offer machines with modular designs and customizable features are likely to gain a competitive edge in the market.

- Focus on After-Sales Services: Providing comprehensive after-sales services, including maintenance, repair, and training, can create additional revenue streams for companies in the metal forming machine tools market. Offering value-added services can help build long-term relationships with customers and enhance brand loyalty.

Read More Reports:

Media Contact:

Company Name: Claight Corporation

Contact Person: Eren smith, Corporate Sales Specialist – U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com

Aus. Site: https://www.expertmarketresearch.com.au