This pulls the armature plate in opposition to the poles to finish the magnetic circuit, forcing it into contact with the friction faces, and slowing its connected load. Friction faces are designed to dissipate heat and to unfold magnetic clamping power evenly throughout the armature face. Electromagnetic friction clutches are just like brakes. The above picture shows how large the transient voltage can be throughout DC switching operations. In this test, the peak of the transient voltage was three.54kV. The brake coil tested is rated for 2.3kV, and switching without any safety would not be splendid for any application. Over time, the transient voltages during switching would degrade the brake coil leading to premature failure. The above picture reveals the DC switching sign when an MOV is put in.

Incorrect hob sharpening. The hob was sharpened with runout through the mounting on the sharpening machine or sharpening arbor. Extreme gash to gash spacing error on the hob. A loose or worn hob arbor finish help on the hobbing machine. Excessive backlash within the hob spindle system on the hobbing machine. Extreme backlash within the work spindle system on the hobbing machine. A unfastened or worn hob arbor end help on the hobbing machine. Extreme backlash in the hob spindle system on the hobbing machine.

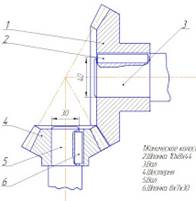

The rotation ensures equivalent gear spindle depth and a consistent variety of teeth on every gear clean. • The accomplished gears are faraway from the milling machine. • The central tool to gear hobbing is the hob, a worm-shaped cutter. The hob makes successive cuts on the gear blank to create the gear teeth. How is the Gear hobbing Machine constructed? Hob- With a rotating cutter often called a hob, the gear blank is rolled. It is a spiral reducing tool used by a gear hobbing machine to carve teeth into blanks. A gear hob, a multipoint reducing device, is used for it. It resembles a worm gear with several straight flutes operating parallel to its axis throughout its circumference. This slows down or stops the movement of the machinery, providing a reliable and efficient answer for movement management in a wide range of industrial purposes. As such, EM brakes are an indispensable part in many areas, from manufacturing and processing to transportation and past. They discover applications in industries corresponding to automation, army, medical, food processing, and packaging. The standard and precision of the shaving tooth floor are improved. After the worm gear hobbing or the flying knife cutting, so as to enhance the standard of the tooth floor and improve the contact between the worm wheel and the worm, the hobbing machine can grind or grind the tooth. The caries instrument is a honing worm made by casting a mixture of abrasive and plastic and resin on a substrate; the grinding worm manufactured from solid iron with grinding abrasive and worm wheel is ground.

At this time, one among the most well-liked coatings is AlCrN (aluminum chromium nitride), which has allowed for extra enhancements in the performance of cutting tools. In the early years when coatings had been first launched, the manufacturers utilizing them learned many classes. The most important take away being that a coating is simply pretty much as good as the bottom materials. In hobbing multiple teeth of the tool, the hob’s teeth, are in contact with the workpiece at the same time. Together with the continuous coupling of the instrument and the workpiece rotational movement, these teeth create the involute tooth gaps in a generating approach. The era process is one of the most basic concepts within the gear hobbing. The chopping instrument geometry can determine cycle instances and the software wear of the process amongst other factors of gear manufacturing.

ASME A17.1 for elevator and escalator brakes. They are often proximity sensors, which make sure that the brake is definitely engaged or disengaged, and/or thermal sensors that measure temperature to see if a brake is turning into overloaded or if something dragging within the system is generating heat. Most machines (e.g., x-ray, scanners, изготовление шестерен по образцу в москве or patient tables) function in a really quiet atmosphere. Even the click of a brake participating or disengaging can be objectionable. Therefore, sound-absorbing supplies are used. Sound-dampening plastic sheets can be constructed into the strain plate to additionally help deaden sound. In addition, inserting plastic sleeves over the standoffs in the brake helps cut back the vibration or rattle of a stress plate when the brake is disengaged. For motorized wheelchairs or scooters, mechanical release mechanisms are required so that patients can nonetheless be moved in case of an electrical failure. The challenge with robotics and servo motors is all the time to make the brakes thinner to scale back the general package deal size.